Stator Coolers & Fin-Fan Radiators

Pressure Worx » Heat Exchangers » Stator Coolers & Fin-Fan Radiators

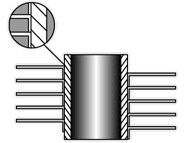

Stator Air & Fin-Fan Coolers

Pressure Worx can design and supply specialty radiator coils for niche applications. These include stator air coolers for the power generation industry.

Our engineering team have designed and supplied many Stator Air Coolers to hydro-electric power stations across New Zealand and Australia. We can refurbish your existing units, or build bolt-in replacements, We’ll assess your process requirements and advise on the best matched materials such that our coolers often perform better than OEM products. Tube and header box material options as well as internal and external paint and protection systems are available.

Option upgrades to coolers can include CuNi 90/10 tubes, CuNi 90/10 tubeplates, Belzona 1341 supermetalglide header coating, addition of sacrifical zinc anodes.

Pressure Worx can do full thermal design of the stator coolers and look at process design enhancements and coil design changes that maintain geometry of the coolers, respecting critical dimensions and pressure drops, but improving performance of the coolers. These enhancements may include finning design and pitch, tube size and rows, internal passing arrangements, tube flow turbulators, construction materials.

We also offer fin-fan &/or industrial radiator solutions for many other niche applications where custom designed or exotic materials are required. As well as plate fins we offer the following helical finned tube options:

EXTRUDED FINS Tubes with extruded fins provide complete protection to the base of the tube as they are hardened during the extrusion process – making them stronger than applied fins. Sometimes known as ‘bi-metallic finned tube’ other benefits of this fin are that corrosion risk between the fin and base tube are almost eliminated and the fin contact with the tube doesn’t degrade, meaning the cooler performance over time due to thermal cycling remains constant. |

|

L FIN (OR WRAPPED FIN) The extruded fin tube is wrapped around the tube and secured at each end to provide some surface protection. L Fin tubes are renowned for maximum heat transfer and enhanced corrosion protection – suiting moderate temperature cooling applications. |

|

LL FIN (OR OVERLAPPED FIN) The fin is wrapped around the tube with an overlapping foot and secured at each end. It offers excellent corrosion resistance and is often used as an alternative for expensive extruded fins in corrosive environments. |

|

G FIN TUBE (OR EMBEDDED FIN) Fin is embedded into the outer wall of the tube, but gives no surface protection. The finned tube is used in general use for continuous process applications; ie refineries, petrochemical, fertilizer and gas plants. |

|

KL FIN (OR KNURLED L FIN) The KL finned tube is manufactured like the ‘L fin’ only the fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube. KL finned tubes give good surface protection to the tube and improve heat transfer. |

|